A “go gauge ensures a bit is not larger than allowed and should slip down the entire bit. As its name implies, it should not go or slip down the entire length of the bit. Above table provides commonly drilling bit sizes that we use for drilling a hole which various API Csg strings generally can be. Use a “no go”gauge to ensure a bit is not smaller than allowed. To correct place the production casing in the well, the necessary bit size to drill the last interval of the well must be 0.375-0.5 or preferably 0.75 larger than the OD of the production Csg, see Table below. Use either a “go” gauge or a “no go” gauge to gauge PDC bits. This jobber length drill bit set includes high speed steel (HSS) drill bits in sizes. American Petroleum Institute Standards for PDC and Rock Bit Tolerances Bit Size (In.) DRILL BIT SET SIZES 1-60 Aircraft Spruce Tap Chart, Chart Tool. The small, medium, and large bit sizes are also the most popular among drillers. The standard bit size is the most commonly used and is the size that is found in most stores. It also represents the oil and gas industry to the public, Congress, state governments, and media. The drill sizes are based on the type of drill bit that is being used. The American Petroleum Institute maintains more than 500 standards and recommended practices. ) In nearly all other countries, metric drill bit sizes are most common (like Bovidix 1902103423.

In the U.S., fractional inch and gauge drill bit sizes are in common use. Its small, but it usually has the drill-bit diameter stamped into the metal the.

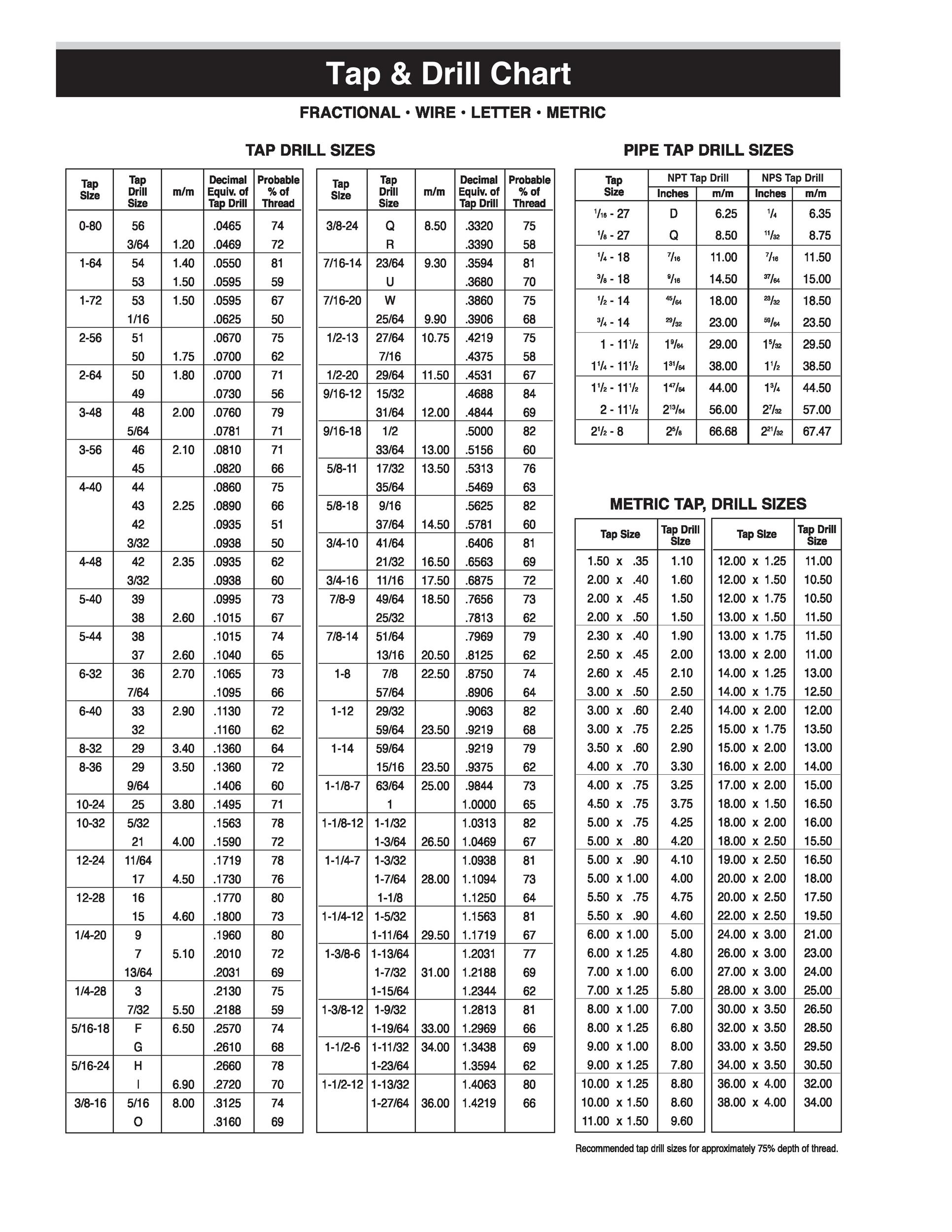

All reputable PDC and tricone manufacturers follow these guidelines. Drill bits can be made in any size, but standards define sets of sizes that are widely produced and stocked. Typical drill bits have markings somewhere on the shank above the threads. I also have included the chart for drill bit size per tap size. This should help whenever you run into a situation you need to drill a pilot hole and are not sure the size bit. To help my readers out, I thought I would add this quick reference chart. These standards, known as API Standards, are part of the backbone of the drilling industry. There is nothing more aggravating when you just don't know what size drill bit to use for a pilot. API certified casing will be within the drift on the below API Casing Chart.

#Drill bit size chart plus#

All major drill bit manufacturers operate within strict plus and minus tolerances as set forth by the American Petroleum Institute. While in-house engineers decide the various individual differences of pdc bits and tricones, API standards enable drilling professionals the world over to communicate clearly. Here you can find our first rivet nut size chart you can use for your repair task and drill size for your 5/16 nutsert drill size. The app can be used in both landscape and portrait orientations, as well as upside-down.API Standards for Manufacturing and API Casing Chart API Standards For Rock Bits And PDC Bits This gives them a well-known appearance, but it also makes them appear identical at first glance. Scroll up within any drill table to reveal the search bar. In case you need to drill a hole and thread it for a screw or bolt. A table with all types combined, for easy comparison of sizesĪ helpful reference tool for anyone dealing with drills of various types: engineers, trades-men, students, tool makers, fitters and turners, fabricators, etc. This should help whenever you run into a situation you need to drill a pilot hole and are not sure the size bit.Tables include common drill bit size types: No typing required, just tap the required size type, and scroll through the chart to find your drill size. An easy-to-use set of charts for viewing various drill bit size types and their decimal inch and metric size equivalents and conversions.

0 kommentar(er)

0 kommentar(er)